Call us today on 1300 36 46 16

Call us today on 1300 36 46 16

Our Heavy Duty Clear PVC Swing Doors are essentially self closing swing doors with PVC or Plastic Sheet panels, they consist of a steel press metal frame making them the toughest construction of PVC Swing Doors on the market and are suitable for fork lift traffic.

Clear Plastic Swing Doors or Clear PVC Swing Doors are ideal for many industrial and commercial door applications including manufacturing Factories, Kitchens, Food Processing Plants, Transport Terminals, Retail Stores, Supermarkets, Cold Storage, Butchers Doors and Hospital Doors etc.

With their self-closing dual swing action, they are an asset in applications such as keeping out drafts, dust control, pest control for rodents or Birds, and continue to provide outstanding results in new applications using their safety, hygiene control, temperature control and sound proof properties.

Not only ideal in applications for personnel foot traffic doors, these doors are comonly used as impact doors where trolleys are pushed through. The doors provide a low maintenance solution in Medium and high traffic situations.

The soft durable flexible plastic sheets fitted in the doors absorb impact by pallet trolleys and padestrians making this type of door one of the safest on the market. These valuable benefits of the doors also relieve impact or stress on the hinge components which is essential for any door in order to provide a low maintenance door solution avoiding ongoing costly repairs to doors in busy applications.

All parts for the Heavy Duty Plastic Swing Doors are constructed using high quality materials. The steel door frame is painted with a tough hammer tone enamel paint ensuring that a high level of protection is applied to the steel door frame. Internal components of the swing door self closing mechanism are also manufactured of high quality material and zinc plated cast door hinges for corosion protection. The flexible Clear PVC Plastic sheets can be replaced, but will deliver years of service even in constant busy traffic areas. Usually the PVC in these door is replaced to restore the clear clarity of the Plastic Sheet for safety reasons after being subjected to years of continious punishment from trolleys and obects impacting the doors causing scratched to the Plastic Panels well before any signs of slitting or tearing of the Plastic Sheet.

Due being designed for heavy duty applications the PVC Sheet Panels are 7mm in thicknesses making them the toughest on the market. 7 mm thick plastic sheet is essential for PVC Swing Doors that are subjected frequent heavy duty use of hand trolleys, Pallet Trolley or any object that may impact the doors etc. This 7 mm thick plastic can take the punishment and makes the doors the safest solution as they absorb impact reducing the risk of injury. Ideal in workshops and warehouses that pose the risk to workers pushing heavy object through doorways.

5 mm thick clear plastic sheet is available, which is used for personnel foot traffic with occassional trolley which also makes the doors more economical and more light weight allowing them to open with a lighter push of the hand as oposed to the 7mm thick PVC Sheet.

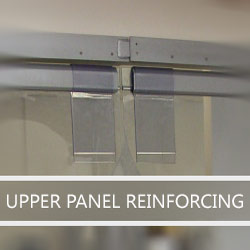

In addition of the two thickness options for PVC Sheet Panels, each PVC Door Panel has an additional section applied of PVC Panel Sheet (Bumper Panels) fitted to the bottom of the doors, the additional thickening panels at the bottom of the doors provide extra support or stiffening to the main PVC Sheet Panel. The Bumper Panels also provide additional strength and weight to the bottom section of the door keeping them taught and straight for optimal sealing efficiency. In addition to the bottom bumper PVC Panels the Heavy Duty PVC Swing Doors also have PVC that wraps around the the doors for additional support that reduces the potential for the Clea PVC Sheet to split due to ongoing punishment. See the Construction Tab for more details on the PVC reinforced sections of these doors.

For Medium Duty PVC Swing Door applications i.e. Foot Traffic, Pallet Trolley traffic more sensitive products etc, we recommend installing our steel framed Medium DutyPVC Swing Doors.

Optional Features:

Our Heavy Duty Swing Doors have an advanced adjustable Heavy Duty self-returning mechanism like no other on the market, consisting of brass components for smooth reliable operation. These doors are made to take the punishment of Pallet Trolleys and Fork Lifts.

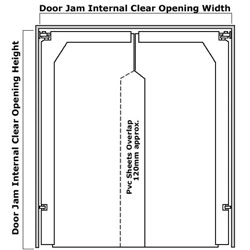

Door Way Requirements –

Due to the heavy-duty self-closing mechanism, door jambs must provide a strong structure. Door ways that do not provide 6mm thick steel to accommodate the M8x16 socket screws will require either Mounting Plates (90mm x 6mm steel flat bar).

Door ways that do not provide adequate strength (Coldroom Panel or metal stud with gyprock et.) May require a steel RHS Box Sub-frame or similar surrounding the door way. Austcold Industries can provide these together with the doors.

Lubrication: It is recommended that periodic greasing of the plunger, prism and lower hinge in undertaken approximately every 2 to 3 months, depending on the environment.

Cleaning: The PVC panel can be cleaned with warm, soapy water and detergent, or, water under pressure, so long as the temperature does not exceed 40 degrees. Do NOT use solvents such as ketones, esters, cyclohexanol, benzenes, trichloroethylene and tetrahydrofuranes.

| Medium-Duty Aluminium Swing Door | Heavy-Duty Steel Swing Door | |||

|---|---|---|---|---|

| Pair | Single | Pair | Single | |

| Maximum Width | 2400mm | 1300mm | 3000mm | 1500mm |

| Minimum Width | 550mm | 460mm | ||

| Maximum Height | 2400mm | 3600mm | ||

| Minimum Height | 550mm | 450mm | ||

| Clear opening loss when @ 90° | 180mm | 90mm | 130mm | 65mm |

| Floor Clearance | 5mm | |||

| Top Clearance | 10mm | 15mm | ||

| Tension adjustment | Incremental tension adjustment | Fully adjustable (tension tool req’d) | ||

| Standard Frame Finish | Clear Anodised | Enamel Paint | ||

| Fork Lifts | No | Yes | ||

| Lock Open | Magnetic | Built In (optional) | ||

| Opening Range | Full 90° Each way | Full 90° Each Way | ||

| Top Hinge secured to | Lintel | Vertical post within 120mm from lintel | ||

| Bottom Hinge secured to | Floor or vertical post at floor | Vertical Post approx 450mm from floor | ||